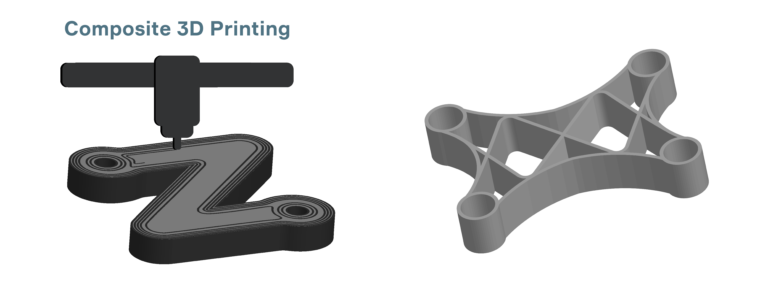

Currently, only 3D printing allows to obtain composite parts with complex shape and high flexible fiber reinforcing paths. With 3D printing you can control anisotropy and utilize potential of fiber reinforcement with maximum efficiency. By the way, that’s why we are called Anisoprint (anisotropic printing or printing with control of anisotropy). You do not need to cut fibers. You can manufacture any hole in composite part without drilling and with reinforcement. Moreover, Anisoprint technology (Composite Fiber Coextrusion) uses thermoplastic matrix that increases impact resistance of a part in contrast to conventional thermosetting composites.