From this video you will know:

- about what type of part is best to reinforce with composite infill

- how to pick up right infill type for your pupposes

- how to set up infill by each type

- about each type of infill and its features

From this video you will know:

From this video you will know:

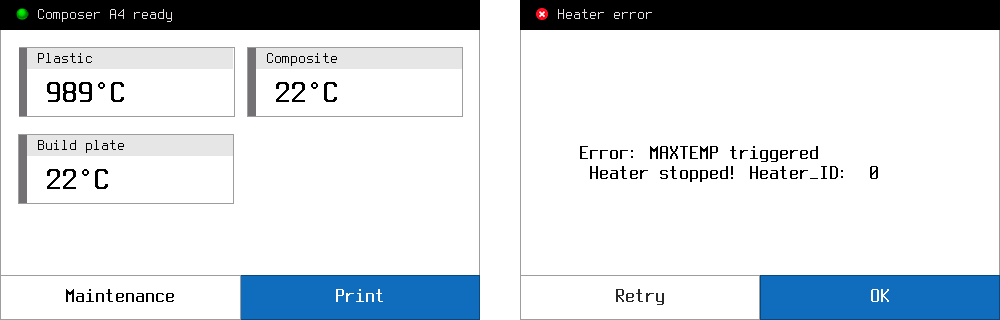

There are two options to get maximum temperature error on the Composer.

This error comes, when Composer get temperature more than 275 C° from one of the extruders (Heater_ID) or more than 125 C° from buildplate.

Caution!

If you set the temperature in gcode more than 275 С° on extruder or more than 125 С° on buildplate, you will get MAXTEMP error, although the printer will work fine.

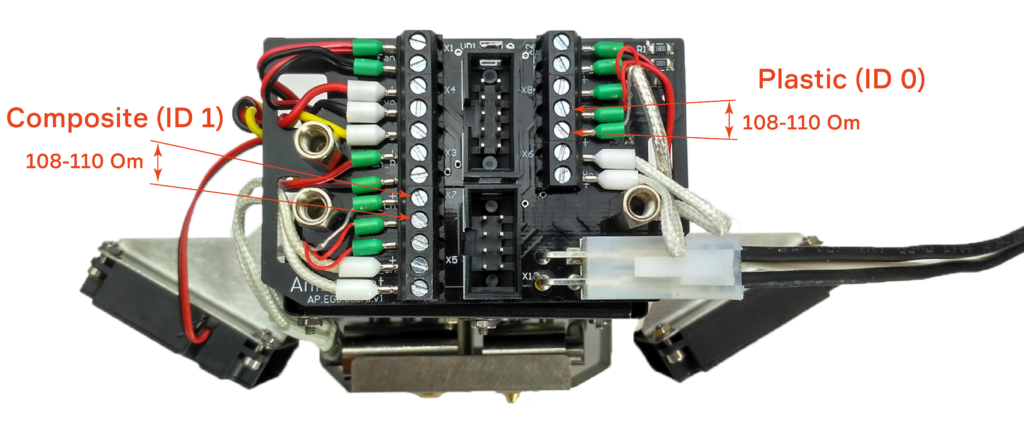

To identify the cause of the error, you need to check the temperature sensor. Operating procedure will be:

If the measured resistance is close to the correct (108-110 Om), it’s means that the temperature sensor works good. You will need to contact your local distributor or write us on support@anisoprint.com

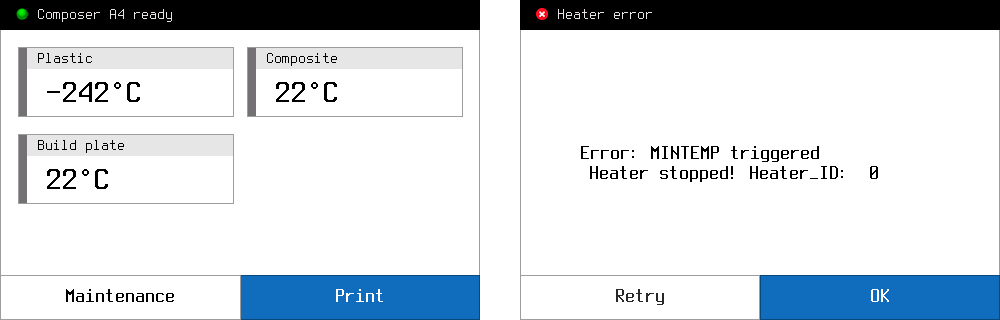

There are two options to get minimum temperature error on the Composer.

This error comes, when Composer get temperature from one of the extruders (Heater_ID) less than 10 C°

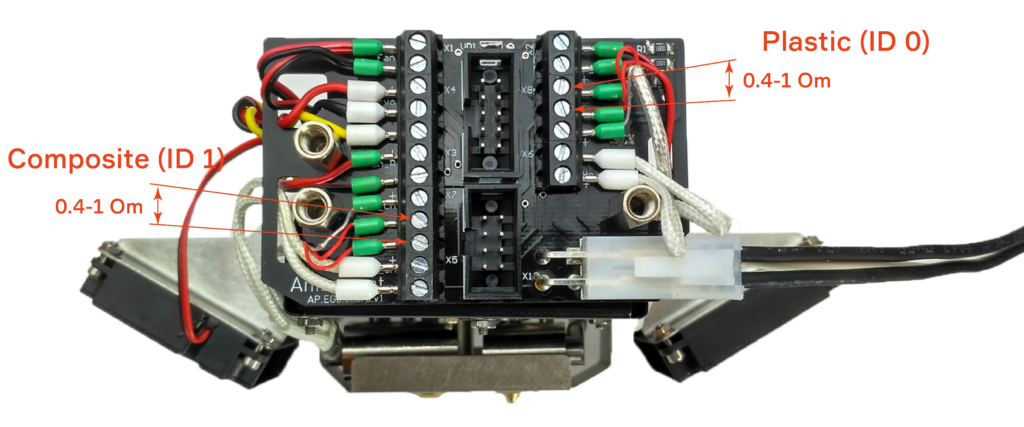

To identify the cause of the error, you need to check the temperature sensor. Operating procedure will be:

If the measured resistance is close to the correct (0.4-1 Om), it’s means that the temperature sensor works good. You will need to contact your local distributor or write us on support@anisoprint.com

From this video you will know:

When some of heating units is fail, you will see error on screen. All heating errors has ID number, which shows the unit in fail.

On the first layer

On the next layers:

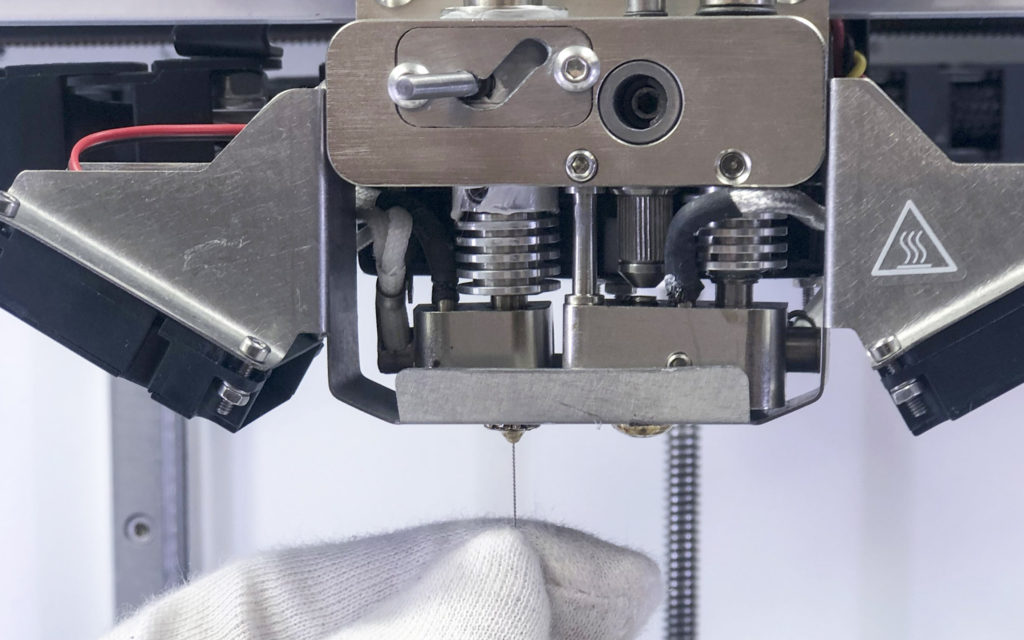

If the nozzle was not enough tighten, during assemble, plastic could leak along the thread up and down. Please tighten the nozzle as it was shown in the instruction

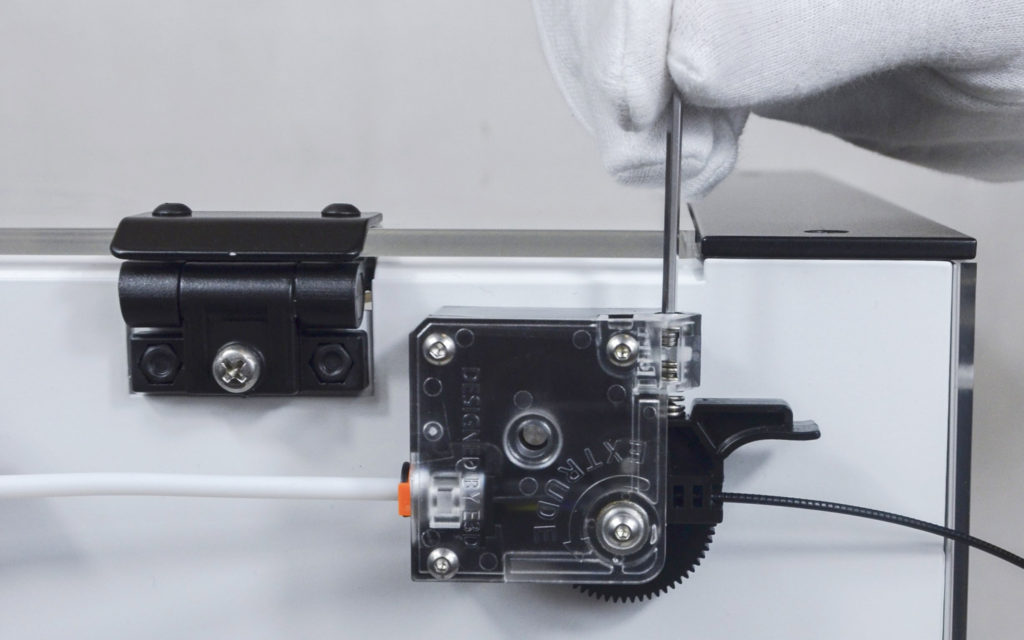

Plastic extruder could fall down if fastern had loosen. Please see assembly instruction to fix this problem