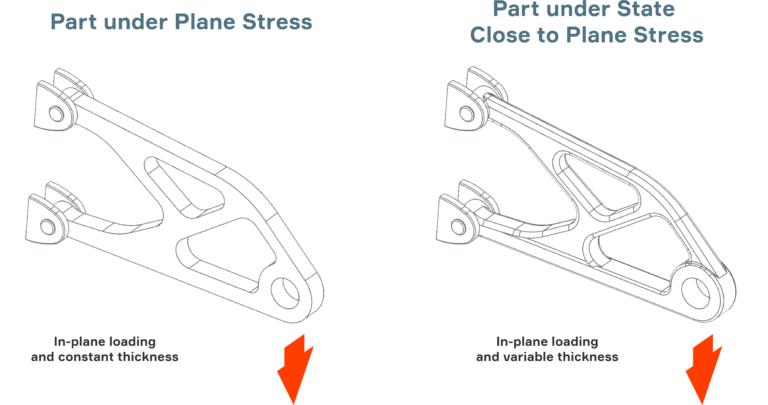

Elements under plane stress means rather thin parts that are subjected to in-plate loads and loads do not change through the part thickness. When out-of-plane loads for real thin parts are small and neglectable these parts can be considered as under plane stress. Manufacturing of such parts is the best way for application of CFC printing.

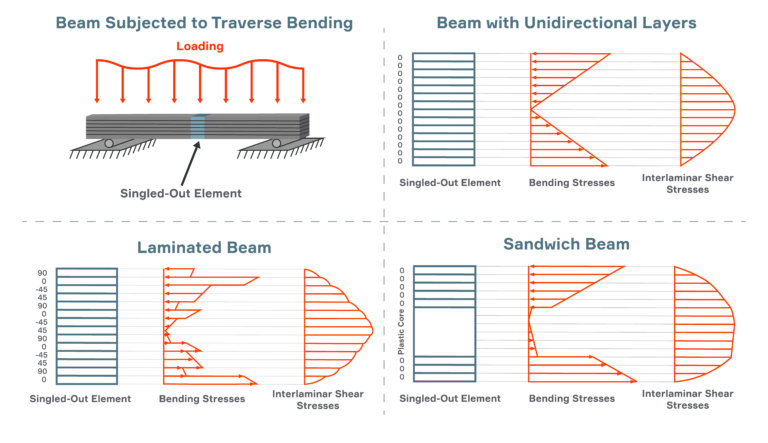

Elements under bending are also mostly subjected to in-plane loading. So, in contrast to plane stress state, acting stresses vary through the element thickness. The greatest stresses are close to the external surfaces of the part. In addition to in-plane stresses, interlaminar shear stresses accompany the bending in most of cases. Maximum interlaminar shear stress is close to central layers. As a rule, the interlaminar shear stress is much less than in-plane stresses and the smaller thickness-to-length ratio for the part the less interlaminar shear stress in comparison to in-plane stress.

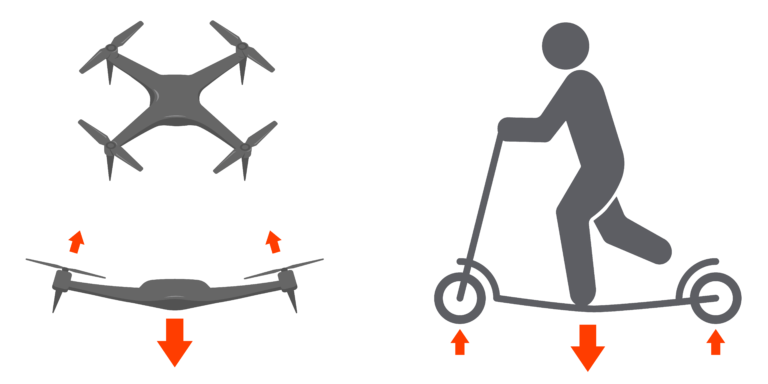

Examples of structural elements under the bending

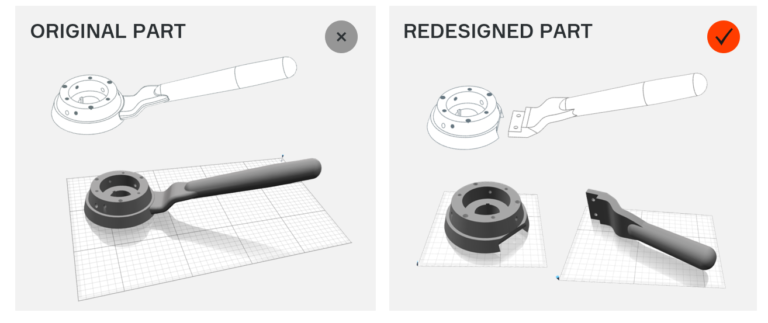

If a loaded structure is complicated and it does not directly comply with description above sometimes an engineer can split such structure on simple structural elements subjected to in-plane loading and the final structure will become an assembly.