Сlog

- Check the operation temperature on printer screen, it should be same as recommended by filament manufacture.

- Most likely you have plastic jam inside the heat break. To solve this problem, you have to disassemble plastic extruder in reverse order than assembly and clean the teflon tube

Under extrusion

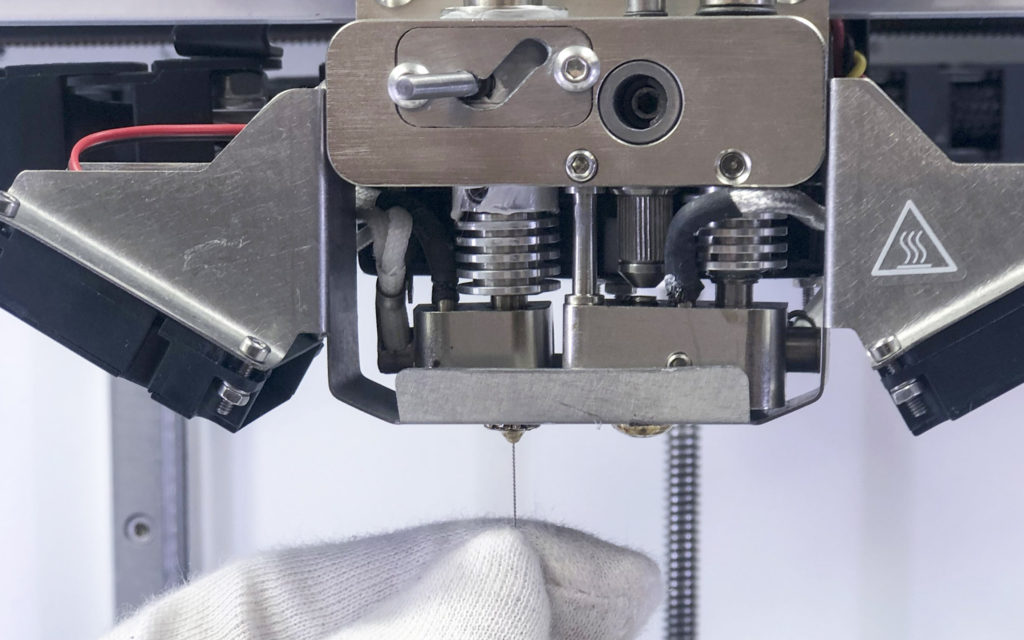

- Clean nozzle hole, using needle from the Tool kit.

- Very often, the problem with the under extrusion is come from wrong Aura setup. Try to change parameters responsible for the flow

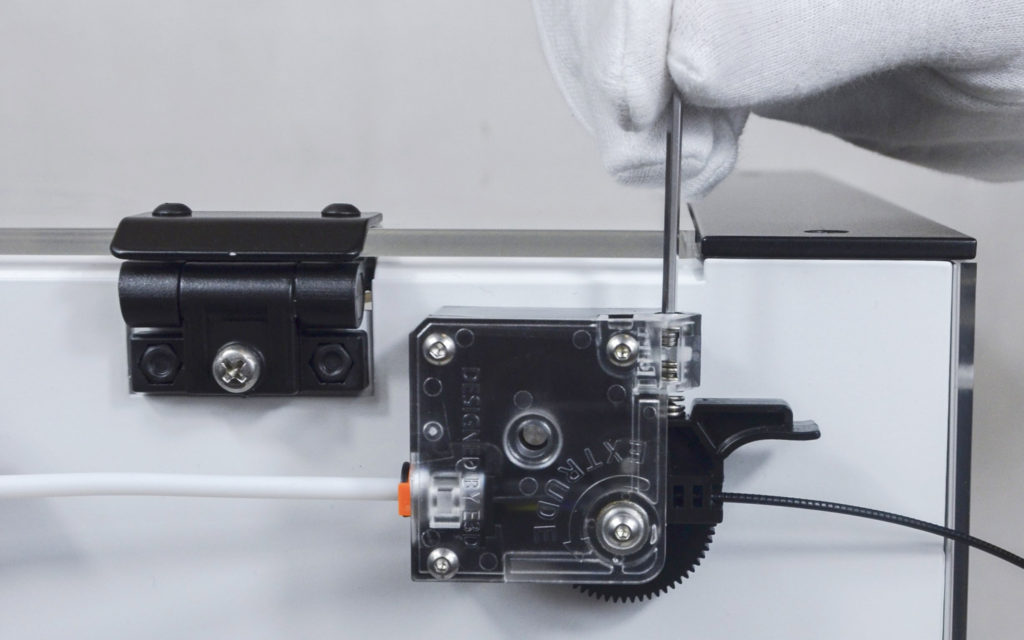

- The filament could not sufficiently pressed in the feeder, tighten the screw using the key from the kit so that the nut is in the middle

Plastic leak

If the nozzle was not enough tighten, during assemble, plastic could leak along the thread up and down. Please tighten the nozzle as it was shown in the instruction

Fall down

Plastic extruder could fall down if fastern had loosen. Please see assembly instruction to fix this problem