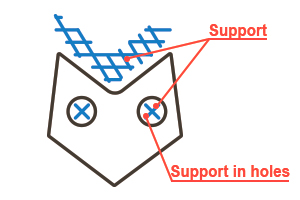

The generate support in holes is the flag which indicates that support will be generated not only on the outside of part but in holes too.

The generate support in holes is the flag which indicates that support will be generated not only on the outside of part but in holes too.

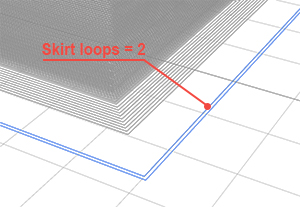

The skirt loops count is the number of skirt loops around a part. Choose the sufficient number to stabilize plastic flow by the end of printing the skirt.

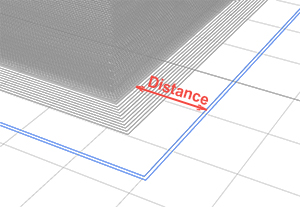

The distance from part is the distance between skirt and part.

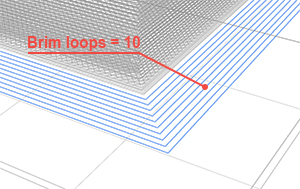

The brim loops count is the number of brim loops around a part. The more loops, the adhesion between parts and a table is stronger.

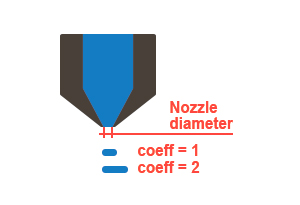

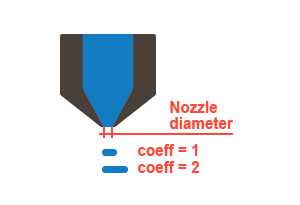

The extrusion width coefficient is the nozzle diameter multiplication factor. That is extrusion width = nozzle diameter * coefficient.

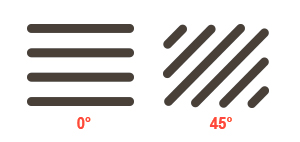

The fill starting angle is the angle of infill rotation.

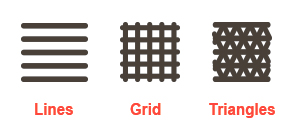

Fill pattern. You could choose from three patterns: lines, grid or triangles, depending on your preferences.

The printing speed is the speed which will be applied to plastic infill printing. Set this parameter as high as possible to speed up printing process.

The extrusion width coefficient is the nozzle diameter multiplication factor. That is extrusion width = nozzle diameter * coefficient.

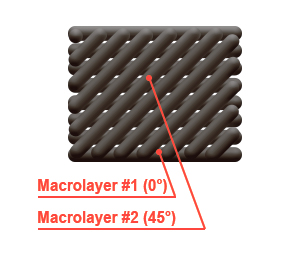

The fill angle offset is the offset angle which is added to current infill rotation angle on each layer. For example, if fill angle offset is 10°, on first macro layer angle is 0°, on second is 10°, on third is 20° etc.