When some of heating units is fail, you will see error on screen. All heating errors has ID number, which shows the unit in fail.

- Heater_ID: 0 – plastic extruder

- Heater_ID: 1 – composite extruder

- Heater_ID: 2 – buildplate

When some of heating units is fail, you will see error on screen. All heating errors has ID number, which shows the unit in fail.

On the first layer

On the next layers:

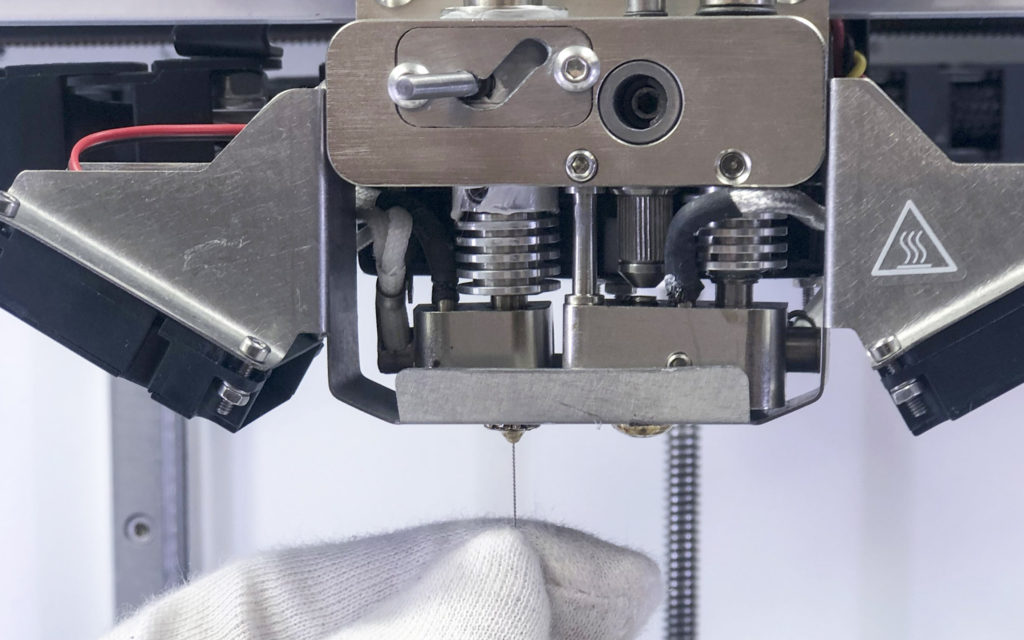

If the nozzle was not enough tighten, during assemble, plastic could leak along the thread up and down. Please tighten the nozzle as it was shown in the instruction

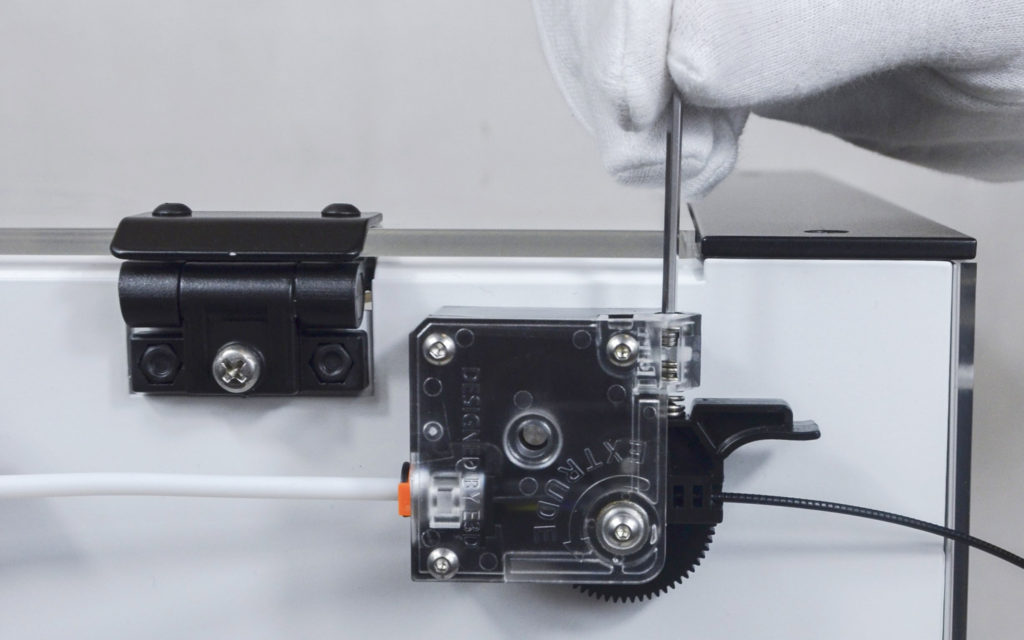

Plastic extruder could fall down if fastern had loosen. Please see assembly instruction to fix this problem