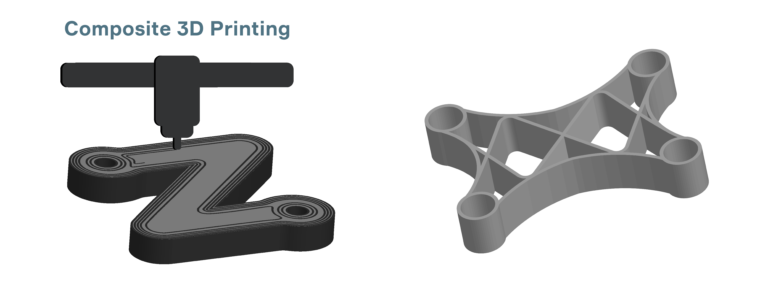

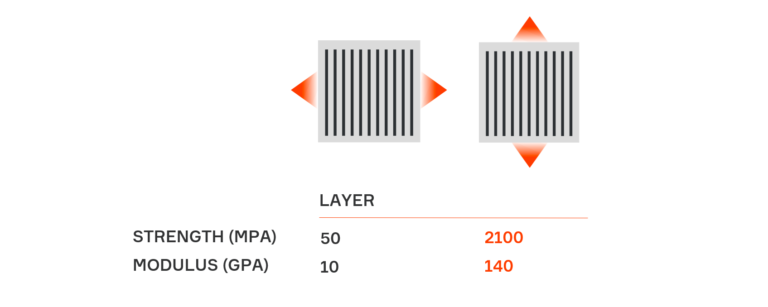

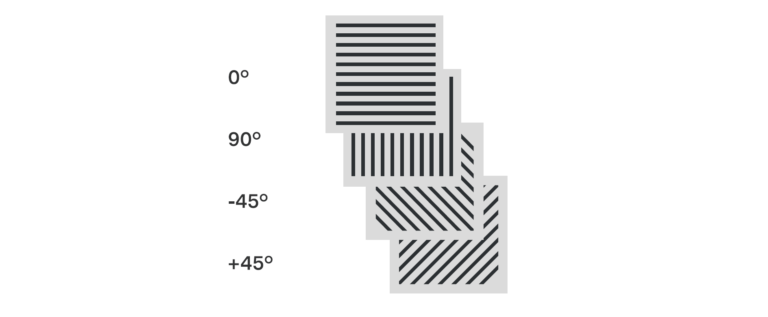

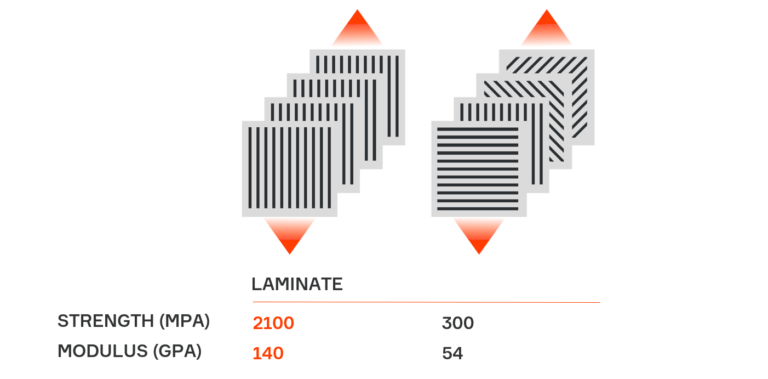

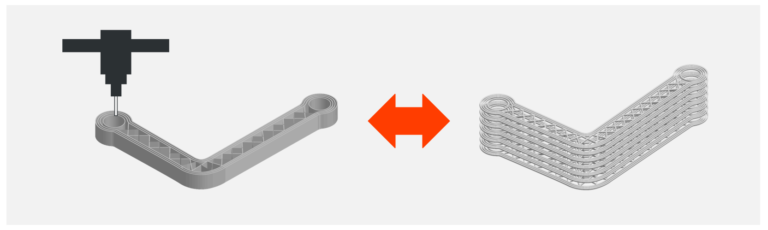

As in Fused Filament Fabrication (FFF), parts made by Composite Filament Co-extrusion (CFC) process are layered structures. Parts printed by Composer consist of flat reinforced layers.

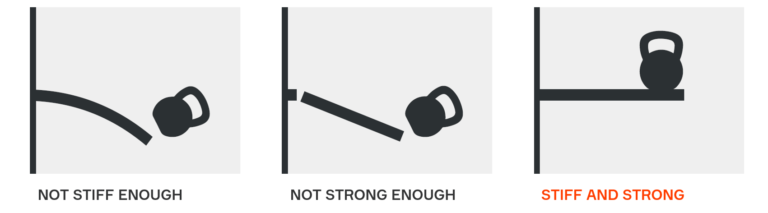

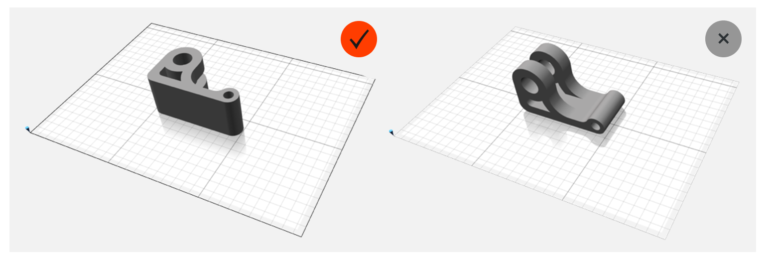

This means that the CFC printed parts can effectively carry loads acting in planes parallel to buildplate surface. Thus, you need to design the part in such a way that all reinforced layers become parallel to the loading plane. At the same time, the loading plane should be parallel to the buildplate surface when you print the part.

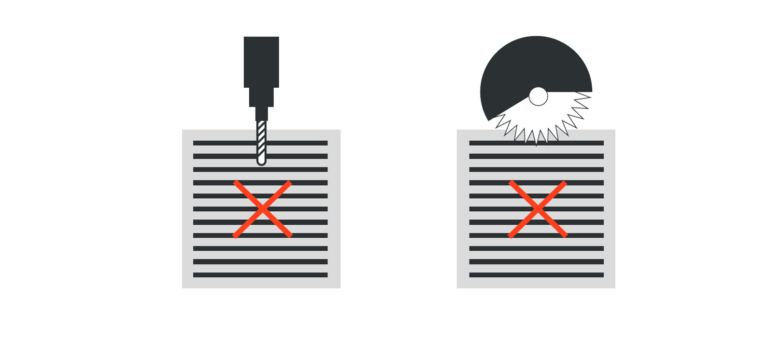

We do not recommend to manufacture very high parts by CFC printing. The high parts do not possess high strength in Z direction and can be broken under interlaminar loads. Recommended height of CFC printed part should not exceed the minimum overall dimension of the part in XY plane. If you plan to print part with big height, do it just by FFF printing.