The fiber diameter is the average diameter of a fiber thread measured in cross section. For the Anisoprint CCF-1.5k this value is 0.34mm.

The fiber diameter is the average diameter of a fiber thread measured in cross section. For the Anisoprint CCF-1.5k this value is 0.34mm.

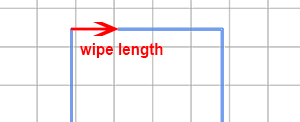

The wipe nozzle length is the length of reverse print head movement. The print head is moving in reverse after retract and is wiping spilling plastic on already printed lines. Choose length enough for stop free plastic spilling after retract.

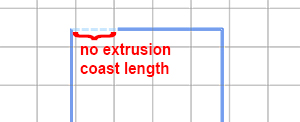

The coast length is the length of the last polygon segment which is printed without plastic extrusion. Plastic goes out only by gravity on this coast segment. Choose length enough to stop free plastic spilling after retract, however, keep an eye on underextrusion.

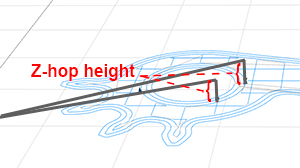

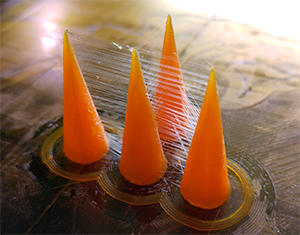

The Z-hop height is the extruder lift up height when moving between print areas. Choose minimum for fast printing process, but enough for prevent part edges hitting and as a result bringing and leaving beads on a part shell. Z-hop may lead formation of strings, however, it is usually easier remove this than removing beads.

The unretract speed is the speed of direct movement of plastic in a feeder. Choose maximum for fast printing restart, however, keep in mind that some feeders can’t handle fast feeding speed.

The retract speed is the speed of reverse movement of plastic in a feeder. Choose maximum for fast printing restart, however, keep in mind that some feeders can’t handle fast feeding speed.

The extra unretract length is the value additional to retract length. On print resuming, if portion of plastic has spilled from an extruder, then volume of plastic in a nozzle becomes less than what it was before travel. If you have noticed for this plastic (especcially for runny) that at the beginning of print there is an underextrusion migrating to normal extrusion, then you shoud set not null for this parameter.

The retraction minimum travel is the sufficient travel length before retraction. In case of short travels it makes no sence to stop for retraction because plastic has not enough time to spill out uncontrolled. Choose this value to maximum, but beware of plastic leaks while travels.

The retraction length on tool change is the length of plastic reverse movement in a feeder. Choose maximum length, taking into account the fact that plastic won’t be fed into this tool for a long time and it is necessary to prevent plastic leakings due to gravity.

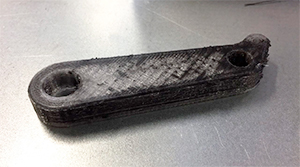

The retraction length is the length of plastic reverse movement in a feeder. Choose long enough length to stop pressure onto plastic in an extruder chamber. Keep in mind that during retract, the extruder stays still, so the longer retract, the longer it stays without movement, which can lead to part melting by the extruder, and leakings for runny plastics.