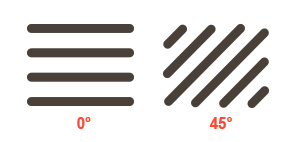

The fill angle is the angle of infill rotation.

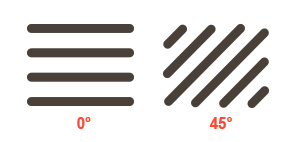

The fill angle is the angle of infill rotation.

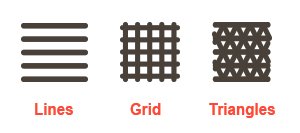

Fill pattern. You could choose from three patterns: lines, grid or triangles, depending on your preferences.

The fill density percent is the percent of filled space inside the support.

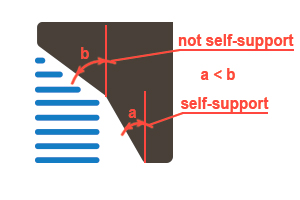

The max unsopported overhang angle up to which part overhang has no need to be supported. If angle is more than the unsupported angle then supports will be generated. The angle is regarding to vertical axe.

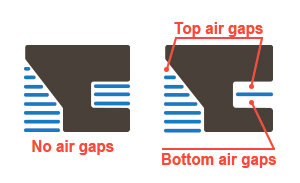

The bottom airgap thin layers count is the number of layers between the bottom of a support and the top of a part. Choose a value with which support will be easy to tear from a part and support will not fall down because of large distance to a part.

The top airgap thin layers count is the number of layers between the top of a support and the bottom of a part. Choose a value with which support will be easy to tear from a part and supported areas will not fall down because of large distance to a support.

The make airgaps flag is the flag which indicates that air gaps will be generated onto and/or under supports.

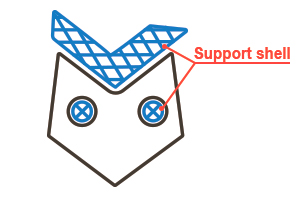

The generate shell for support is the flag which indicates that external shell will be generated for supports.

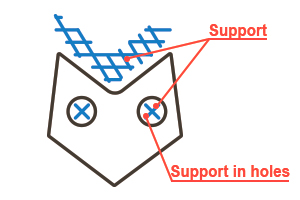

The generate support in holes is the flag which indicates that support will be generated not only on the outside of part but in holes too.

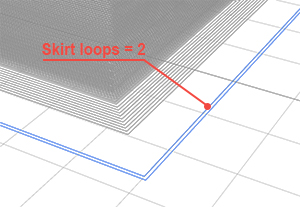

The skirt loops count is the number of skirt loops around a part. Choose the sufficient number to stabilize plastic flow by the end of printing the skirt.