Residual dirt, fiber remnants and degraded plastic are slowly accumulated inside extruder during printing process. To clear the dirt, or remove small fiber pieces from an extruder do the following

- Using the 2mm hex key from Tool Kit loosen the side screws of fan bracket. Remove the fan bracket carefully, fan bracket stays hang on wires.

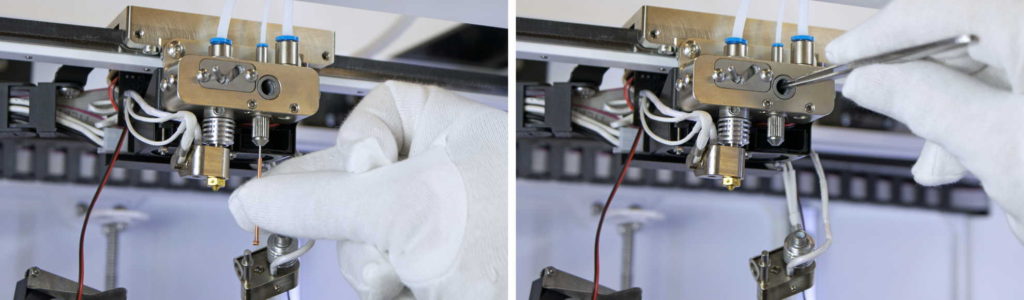

- Heat the composite extruder up to 200C° . Using the 9 mm socket wrench unscrew the composite nozzle from the composite extruder – turn it clockwise, do not use too much force to avoid damage of the composite nozzle

- Check the сomposite nozzle, there should be no fiber pieces inside. If they are there, remove them with tweezers.

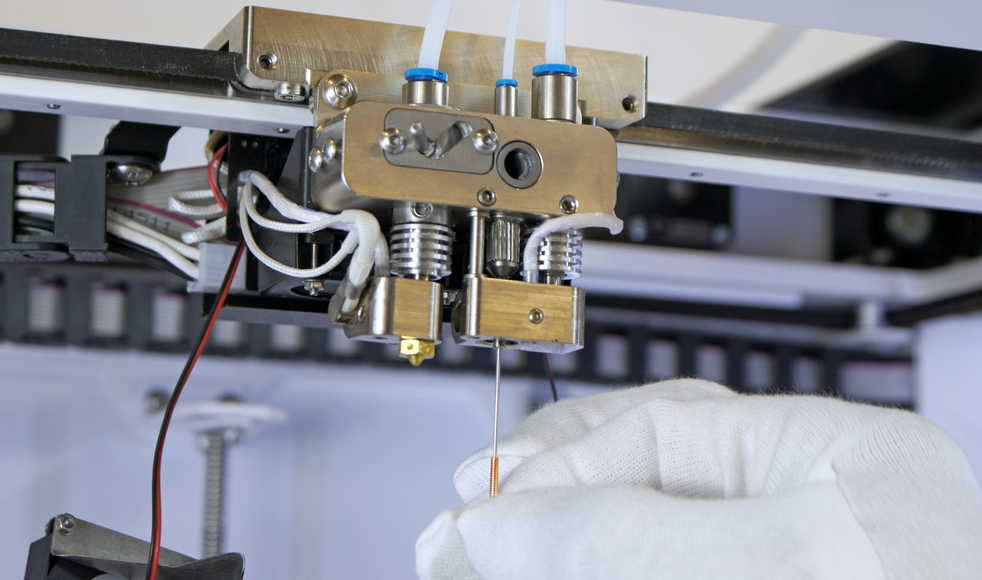

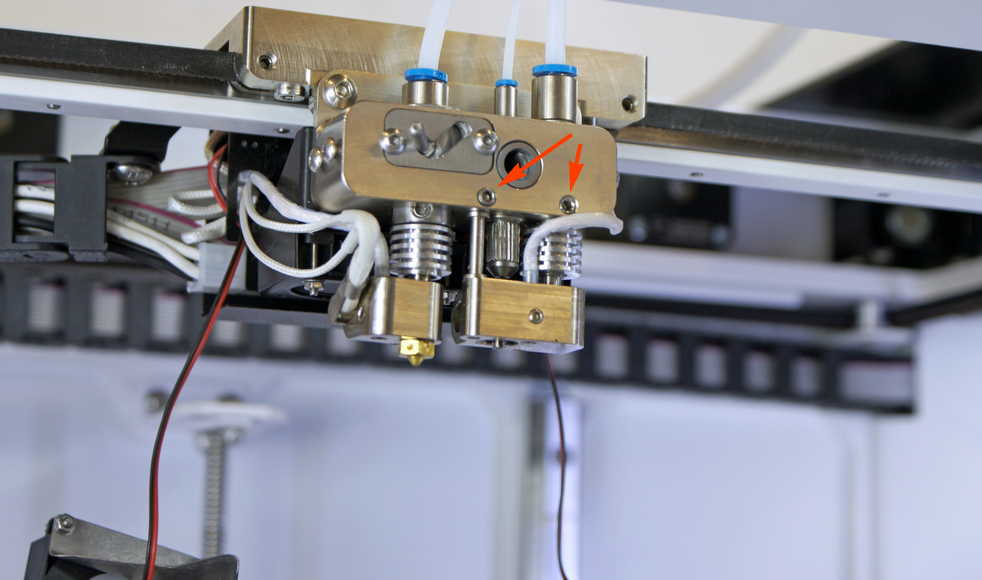

- Heat composite extruder up to 250C°. Clean the guide tube in composite heater block with cleaning needle from tool kit or you can use any stiff steel wire with 0.8 diameter.

Caution!

Further only In the case of heavy clog.

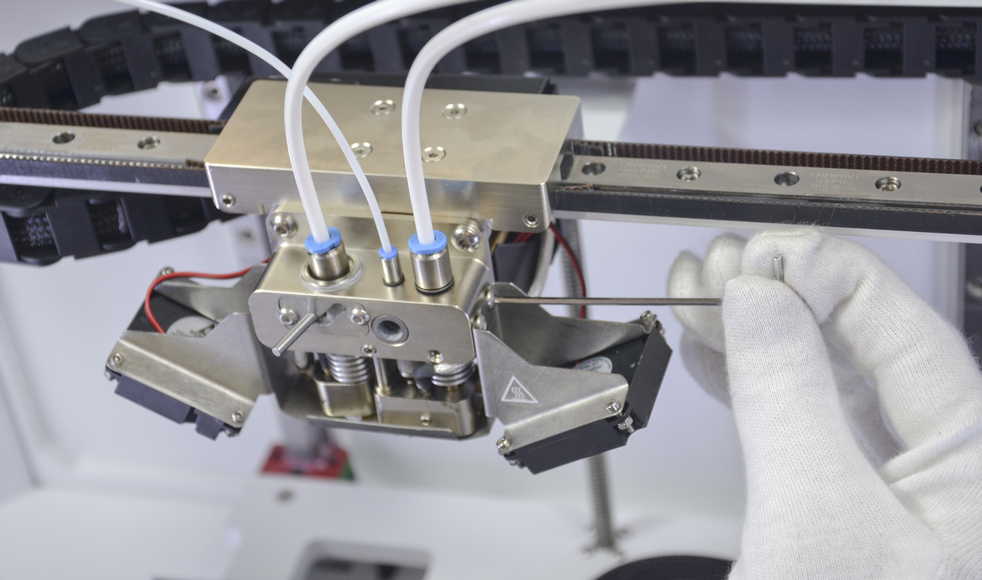

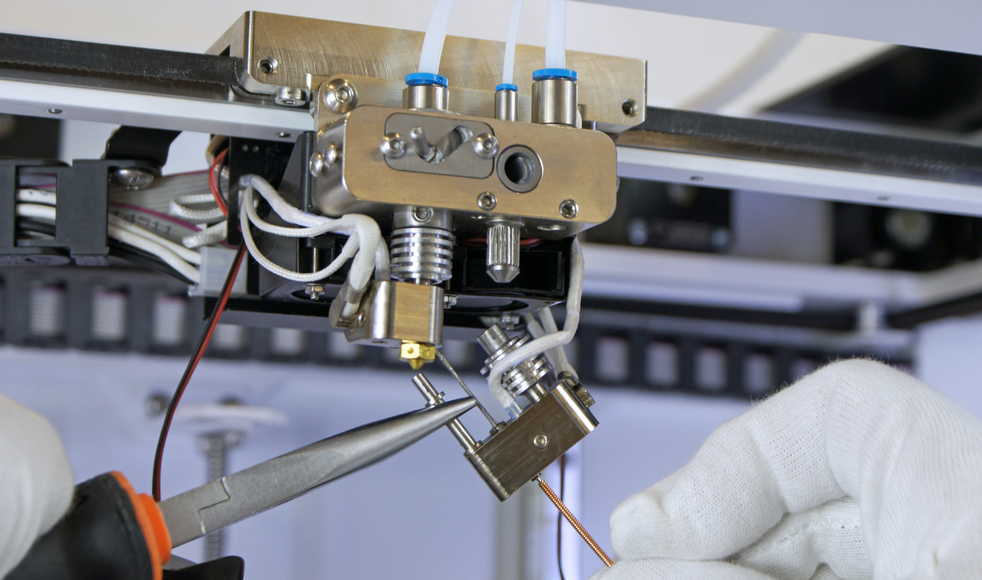

- Using the 2 mm hex key from tool kit loosen set screws and pull down the composite extruder.

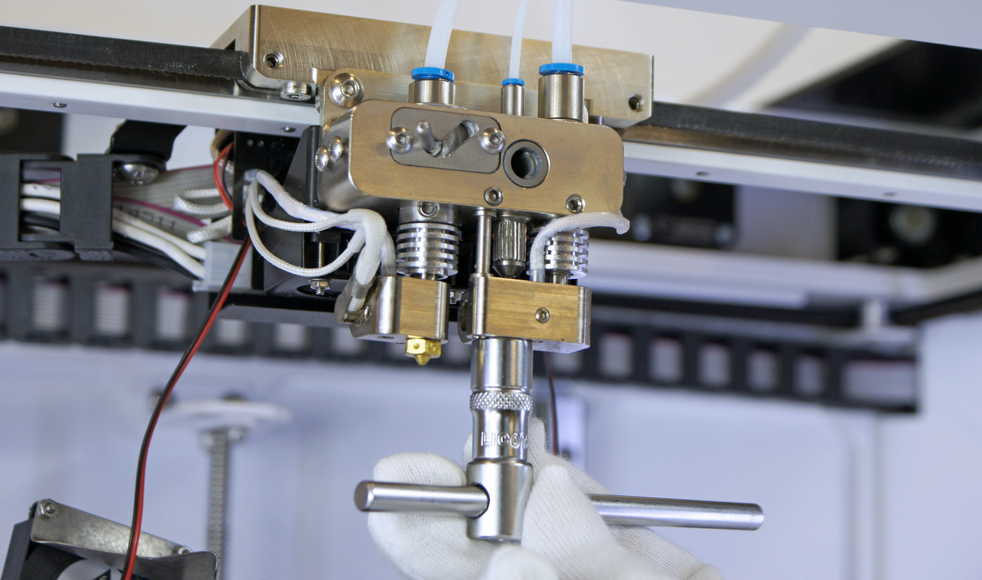

- Heat composite extruder up to 250C°. Hold it by pliers, and clean the guide tube in composite heater block by cleaning needle.

- If some fiber remains at cutter sleeve or guide bush – clean it with tweezers.