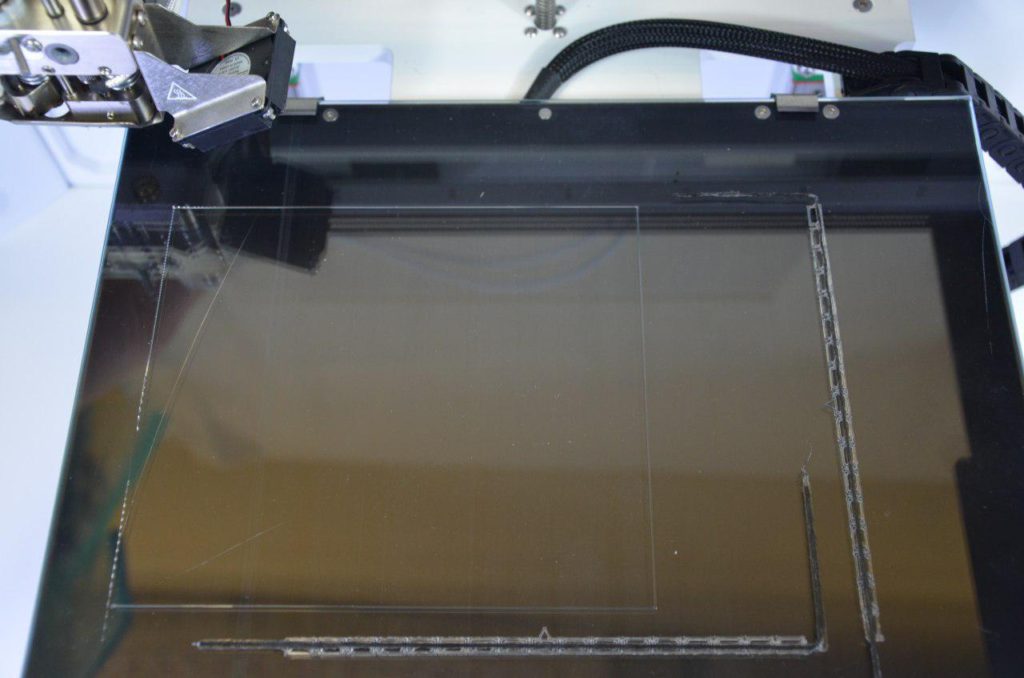

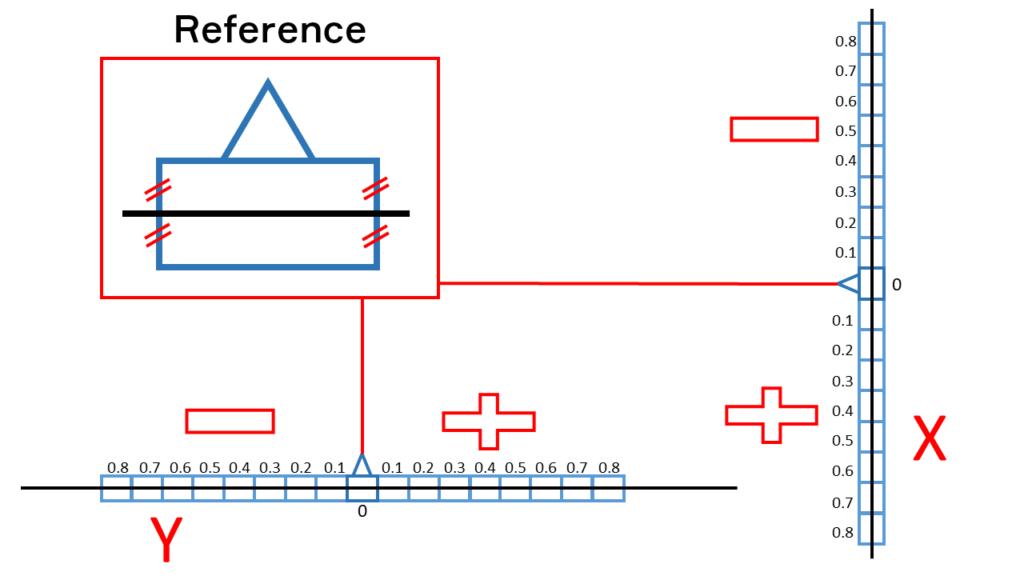

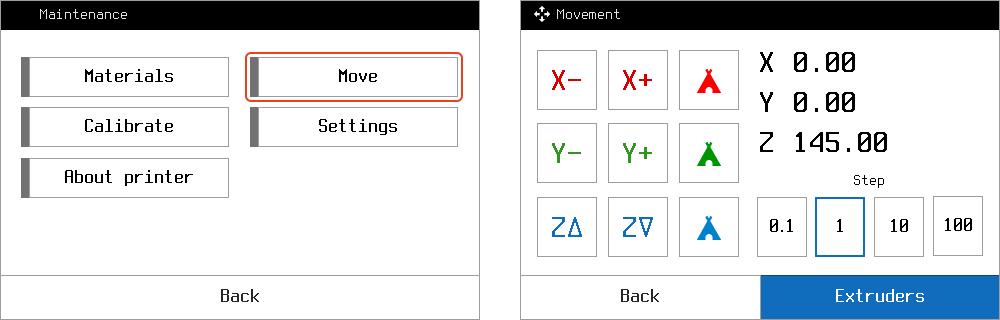

You can move the printhead of your Composer to any point in the build area. To do this, on the Main Screen press Maintenance > Move. Choose a move distance and press axis arrows to move.

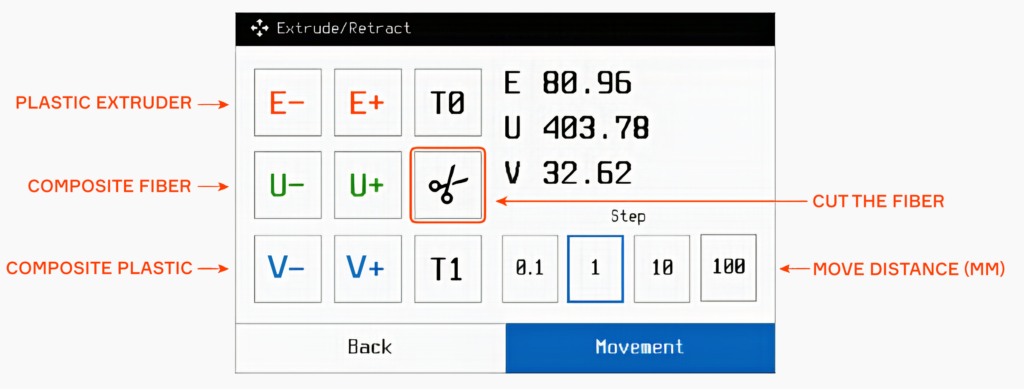

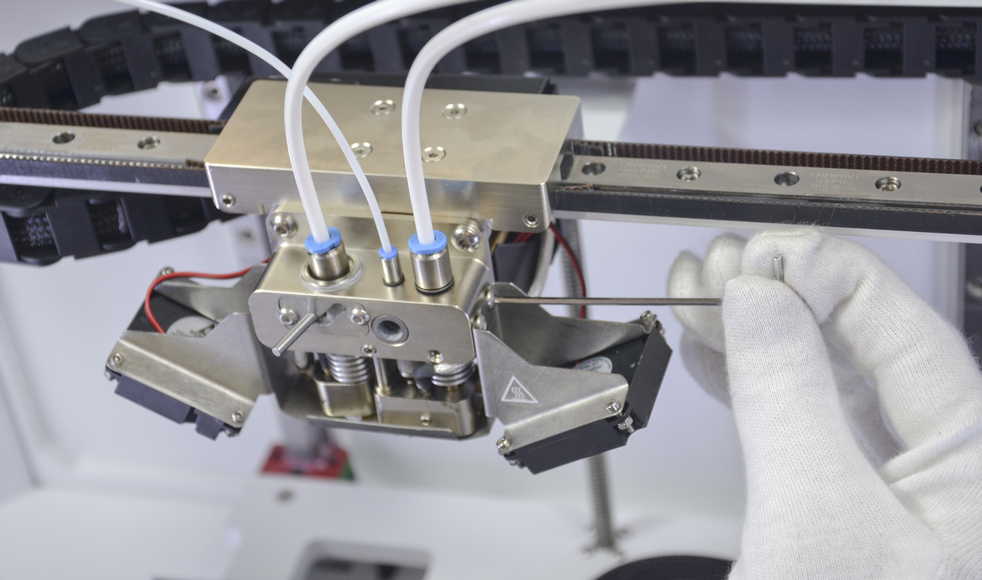

To move a filament back or forward, press Maintenance > Move > Extruders, choose a move distance and use extruder arrows to move. E stands for plastic filament in the plastic extruder, U and V for composite fiber and composite plastic respectively.

You can also cut the fiber by pressing the Scissors icon.