For some reasons (incorrect printing parameters or improper maintenance), composite fiber may stop feeding, i.e stop coming out of the heat block. It means that composite fiber is clogged inside the extruder. For this case, a cleaning procedure is described below.

- Heat composite extruder up to composite plastic printing temperature (or a bit higher). On the main screen, press the Composite extruder temperature button and set required temperature (see point 1. from COMPOSITE EXTRUDER CHANNEL CLEANING, p. 8.3).

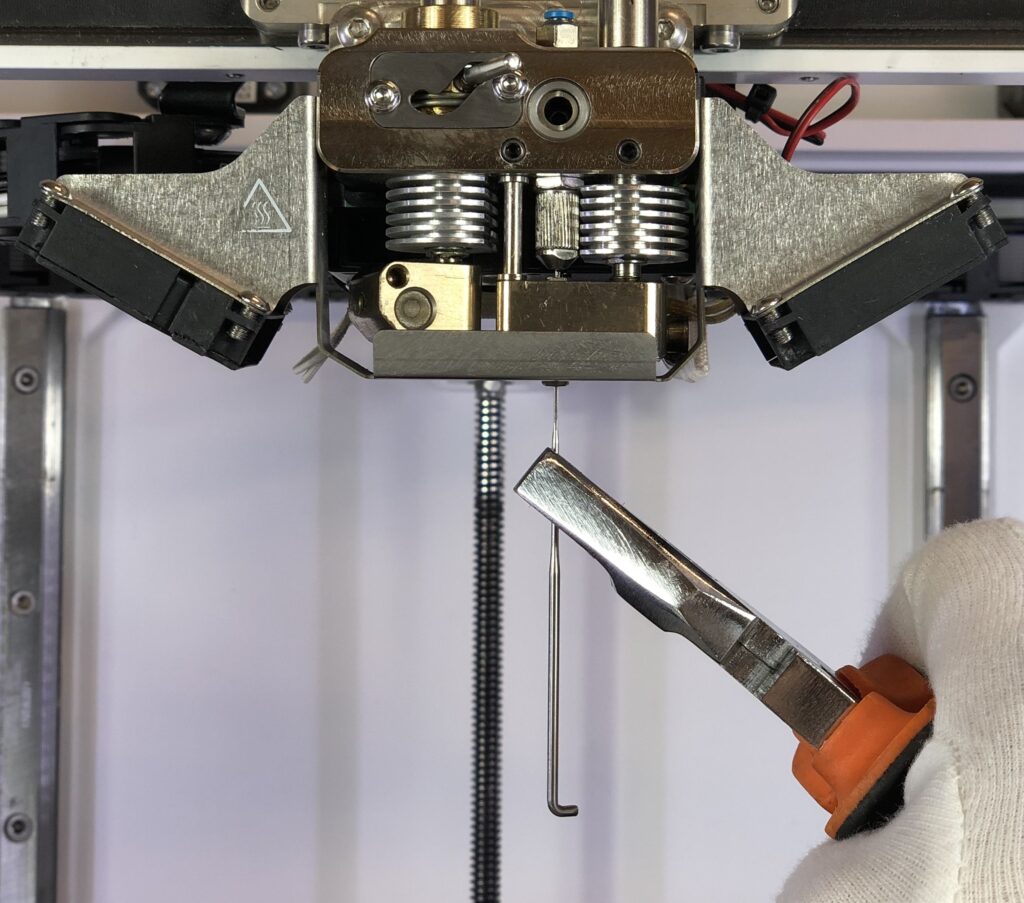

- If there are some fibers, sticking out of the heat block, remove them, by pulling down with tweezers.

- Clean the contact surface of the composite nozzle by brass wire brush from the set of cleaning tools (see point 2. from COMPOSITE EXTRUDER CHANNEL CLEANING, p. 8.3).

- Insert the barbed needle from the set of cleaning tools into the composite nozzle. Spinning the needle, push it through the extruder, until the end of the needle is in the inlet hole of the extruder. Be careful not to break the needle. Pull the needle down

and clean it by tweezers so the barbs are clean. You may need to push/pull the needle with effort if the fiber is clogged tight, use pliers for this purpose.

- Remove material, pushed out of the inlet of the extruder with tweezers.

- Repeat points 4. – 5. until the needle is clean and the remains of the material stop pushing out of the inlet hole of the extruder.

- From the main screen go to Maintenance > Move > Extruders, change Step to 10 mm and feed 50 mm of the composite plastic filament (press V+ button 5 times). You should see clean plastic, exiting from the nozzle and inlet.