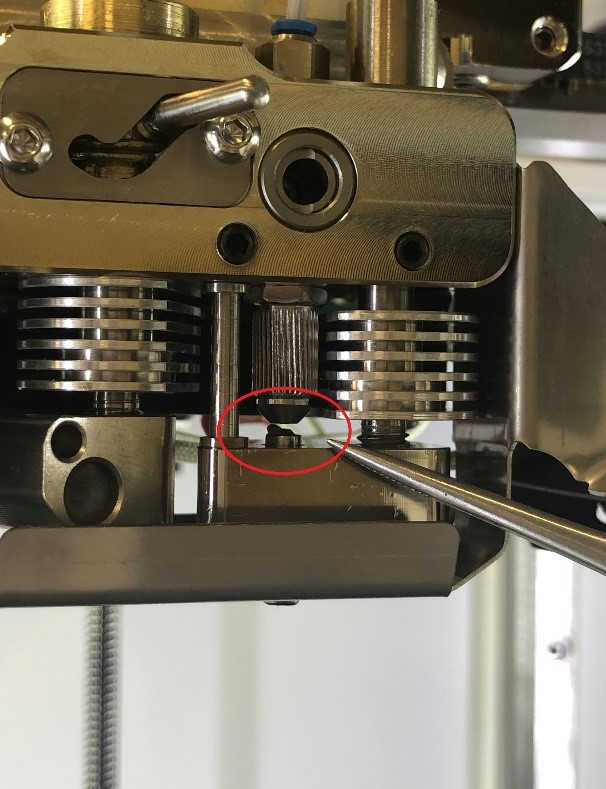

There are several issues that may cause plastic leakage. If such an issue occurs, heat the composite extruder and remove plastic, leaked out of the heat block inlet with tweezers. Before this procedure, cancel the active print if there is one.

After the leaked out plastic is removed, go through the issue identification procedure described below:

- Check Z axis calibration. Incorrect Z axis calibration may cause plastic leakage on the inlet of the composite heat block. Go through Z AXIS CALIBRATION procedure, p. 7.5.

- Check Z offset calibration. Low Z offset value may cause accumulation of composite plastic inside the heat block and further leakage from the inlet. Go through Z OFFSET CALIBRATION procedure, p. 7.6.

- Check whether the composite plastic was dried before printing. The presence of moisture in filament will cause boiling of theliquid during printing, which will result in an uneven supply of composite plastic. Dry plastics in accordance with the material

specification if required.

NOTICE: lack of composite fiber in the heat block or stop of its feed can cause plastic leak of the composite heat block inlet. This can happen during the composite plastic loading or its manual feed. The plastic fills the heat block and goes out through both the nozzle and the inlet simultaneously.

NOTICE: lack of composite fiber in the heat block or stop of its feed can cause plastic leak of the composite heat block inlet. This can happen during the composite plastic loading or its manual feed. The plastic fills the heat block and goes out through both the nozzle and the inlet simultaneously.