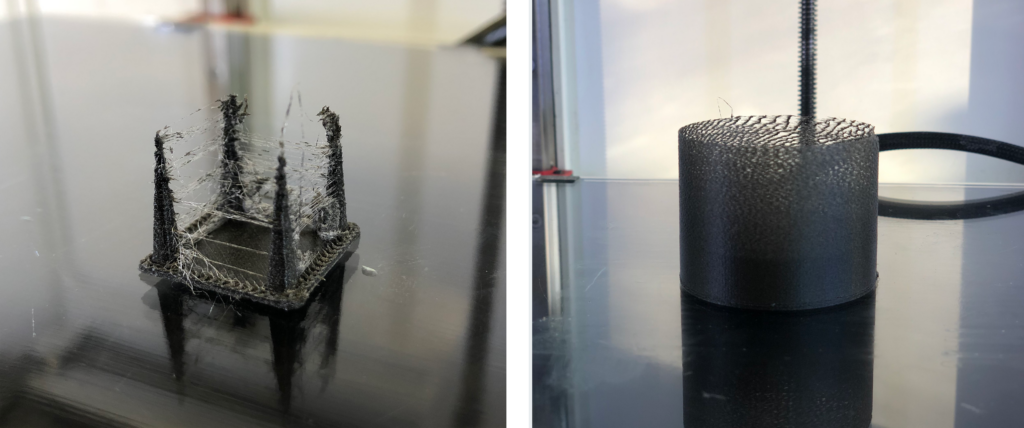

There are some issues that may cause poor quality of the final part, including plastic under-extrusion, plastic stringing etc.

- Check whether the plastic was dried before printing. Most plastics tend to absorb moisture that affects the quality of the printed part. Dry plastics in accordance with the material specification if required.

- Check the nozzle surface cleanliness. Clean the nozzle by brass brush from the tool kit if required (see PLASTIC NOZZLE CLEANING, p. 8.2).

- If points 1. and 2. are met, then the nozzle is worn out. Long-term operation of the nozzle may cause wear that manifests in strips, gallings, or roughness of the inner surface of the nozzle, so you may need to replace the nozzle. Go through the PLASTIC NOZZLE REPLACEMENT procedure, p. 8.1 if required.