From this video you will know:

- about what type of part is best to reinforce with composite infill

- how to pick up right infill type for your pupposes

- how to set up infill by each type

- about each type of infill and its features

From this video you will know:

From this video you will know:

From this video you will know:

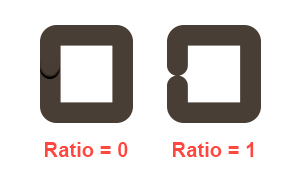

When this parameter is 0 plastic polygon is fully closed. When this parameter is 1, plastic polygon has empty gap that is equal to extrusion width. Choose the value that is differ from 0, if you’ve seen the plastic overextrusions on polygon seam.

When this parameter is 0 plastic polygon is fully closed. When this parameter is 1, plastic polygon has empty gap that is equal to extrusion width. Choose the value that is differ from 0, if you’ve seen the plastic overextrusions on polygon seam.

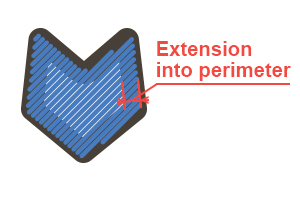

The infill extension into perimeters is the length by which infill penetrate perimeters. Choose the length that provides infills fusion together with perimeters.

The do wipe nozzle flag is the flag which indicates that plastic polygon will have reverse movement after full polygon print has ended.

The do coast before retract is the flag which indicates that plastic polygon will have dry (without plastic feeding) segments in the end.

The do z-hop when retracted flag is the flag which switches on/off a nozzle z-hop mode when travel has retract. Choose this mode to improve external shell surface quality, but keep in mind that it sligtly slow down print process. Besides, it may produce strings between print areas, but usually it is easier to remove them than plastic drops.

The do retract on changing layers is the flag which indicates that plastic will be retracted on layer change even if there is no XY movements during change layers.