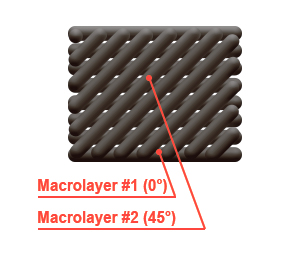

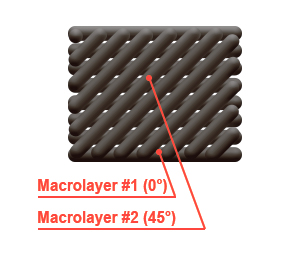

The fill angle offset is the offset angle which is added to current infill rotation angle on each layer. For example, if fill angle offset is 10°, on first macro layer angle is 0°, on second is 10°, on third is 20° etc.

The fill angle offset is the offset angle which is added to current infill rotation angle on each layer. For example, if fill angle offset is 10°, on first macro layer angle is 0°, on second is 10°, on third is 20° etc.

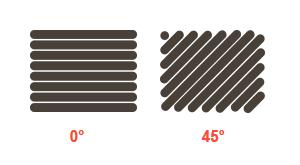

The fill starting angle is the starting angle of infill rotation.

The printing speed is the speed which will be applied to plastic infill printing. Set this parameter as high as possible to speed up printing process.

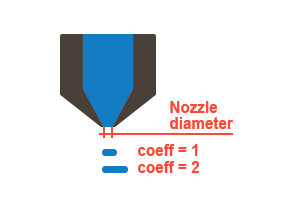

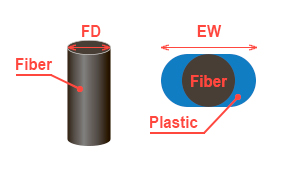

The extrusion width coefficient is the nozzle diameter multiplication factor. That is extrusion width = nozzle diameter * coefficient.

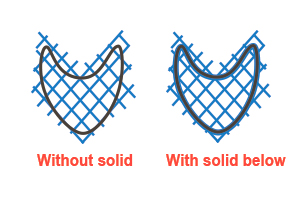

The solid plastic layers below fiber count is the number of macrolayers in which solid infill will be generated. It needs to prevent fiber fall through cellular infill.

The solid plastic layers above fiber count is the number of macrolayers in which solid infill will be generated. This parameter not used as solid plastic layers below fiber, so you may want to use it only for cover up fiber polygons from above.

The printing speed coefficient is the multiplication factor which will be applied to fiber print speeds.

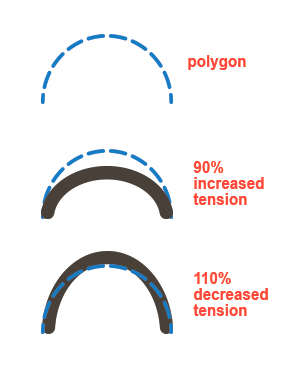

The fiber feedrate is the percent of full presumed path length. Descrease this parameter to increase fiber tension and increase this parameter to descrease fiber tension.

The extrusion width is the width of composite material (plastic + fiber).

The printing speed is the speed which will be applied to plastic perimeters printing. Set this parameter as high as possible to speed up printing process.