The printing speed is the speed which will be applied to external shell printing. Set this parameter to the sufficient minimum to improve surface quality of parts. The slower printing speed, the lower chance to obtain vertical ringing on parts.

The printing speed is the speed which will be applied to external shell printing. Set this parameter to the sufficient minimum to improve surface quality of parts. The slower printing speed, the lower chance to obtain vertical ringing on parts.

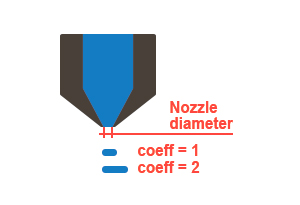

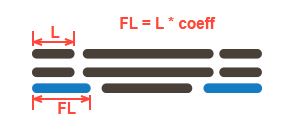

The extrusion width coefficient is the nozzle diameter multiplication factor. That is extrusion width = nozzle diameter * coefficient.

The first layer printing speed is the speed of printing of all entities at the first layer. You may want to set this value a little slower than average speed on other layers to improve adhesion between parts and a table.

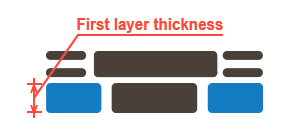

The first layer height is the height of the first layer. Set this parameter a little bit larger that other microlayers to compensate table relief. The first layer has no microlayers structure as macrolayer and it doesn’t comprise into any macrolayer as other microlayers.

The first layer extrusion width coefficient is the extrusion width multiplication factor. It has affect on extrusion width for all entities on first layer and consequently on plastic amount.

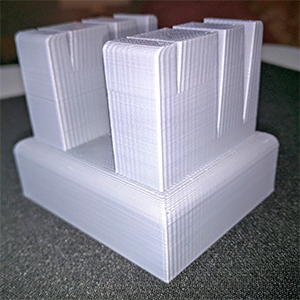

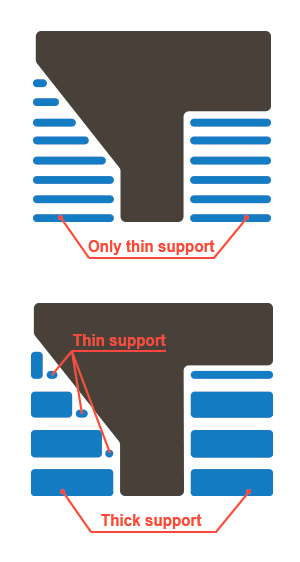

The thin support layer height is the height of layers which contain thin supports. Thin supports are generated in the areas which can’t be converted into thick support.

The thick support layer height is the height of layers which contain thick supports. The thick support is calcalated by intersection of thin support layers. Set thick support layer height as large as possible to speed up the print process.

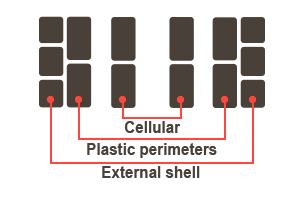

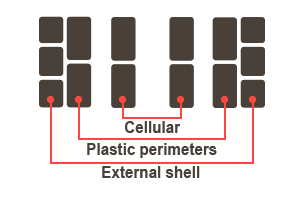

The infill layer height is the height of layers which contain cellular infill. The cellular infill is inside plastic perimeters and leaves an empty space in a part.

The plastic perimeters layer height is the height of thick plastic shell. Set this value as much as possible to speed up the print process. The thick plastic perimeters make parts more strong. Because plastic perimeters are not visible they can be printed thicker than an external shell to speed up the printing process.

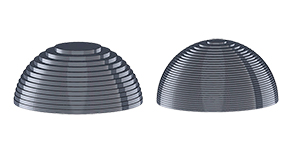

The external shell height is the height of thin plastic layers which build up an external shell of a part. The thinner external shell, the more precise and accurate the part looks.