This User Manual is the main document for Composer CFC printers, it is provided with the delivery package. The Manual guides correct operation, maintenance, and troubleshooting of Composer CFC printers manufactured by Anisoprint.

Please follow this User Manual when operating and maintaining the equipment. Failure to follow the guidelines may lead to poor quality of printed parts, damage to the printer, or cause injury, please read the User Manual carefully.

Category: Uncategorized

Z offset calibration

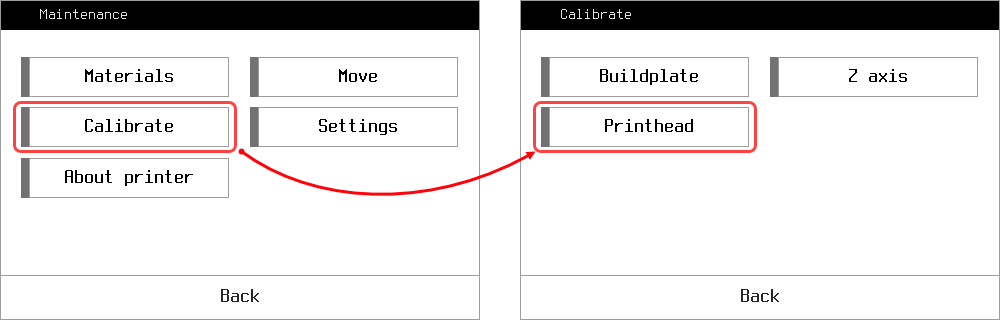

This procedure is critical for obtaining quality prints with continuous fiber. The basic procedure is automated in the printer menu. Go to printer Maintenance menu and hit Calibrate – Printhead.

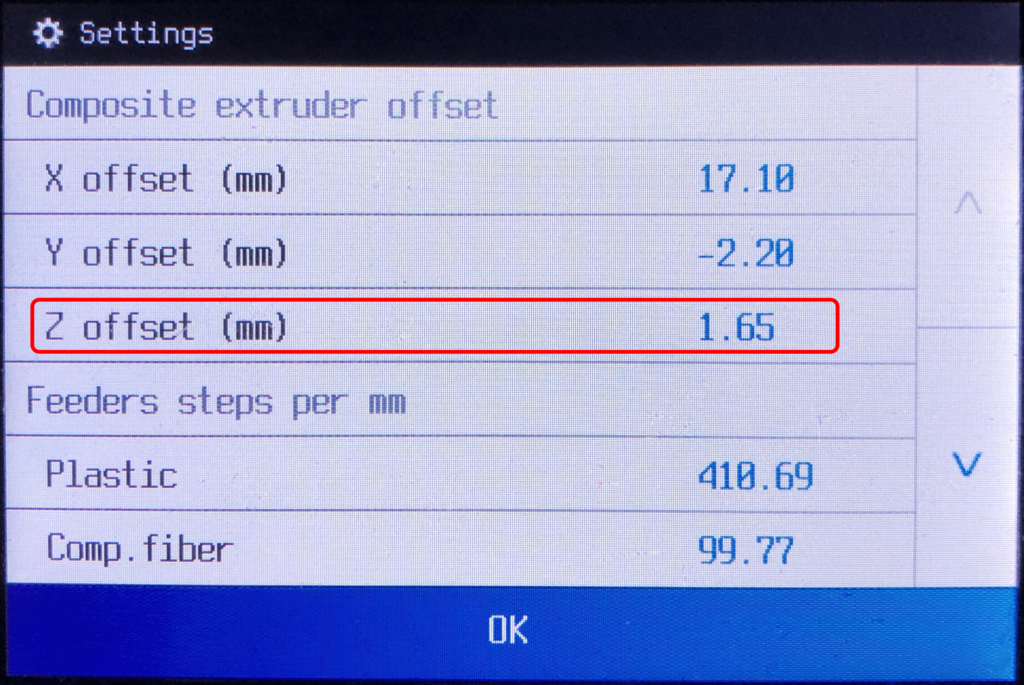

Choose Comp. Z-offset button and follow the instructions on the screen. It is important to understand, that composite Z-offset value is measured relative to Z axis position – it is just a distance between plastic and composite nozzles tips on Z. It means that this calibration always must be done after Z axis calibration.

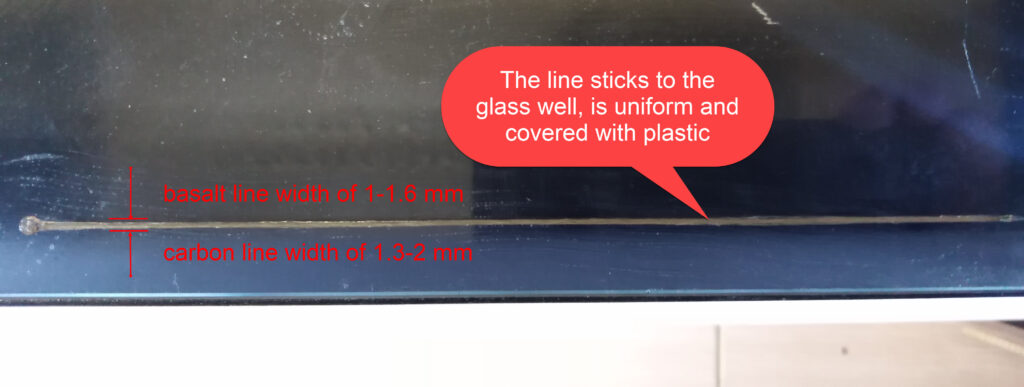

The full calibration sequence is also shown in our education video. But how can you determine you need this calibration in the first place? This is simple: at every composite print start, you will see a calibration fiber line printed at the front edge of the buildplate.

If you see the line is to high above the glass and doesn’t stick, it means the composite nozzle is too high, so the offset needs some adjustment. If the line is too wide, or the nozzle scratches the glass so the fiber cannot go out, it means the nozzle is too low.

After calibration is done, you might want to check yourself with offset value in Settings. Typical values for z-offset will lie within 1.6-2.3 mm.

Reinforcement with Aura

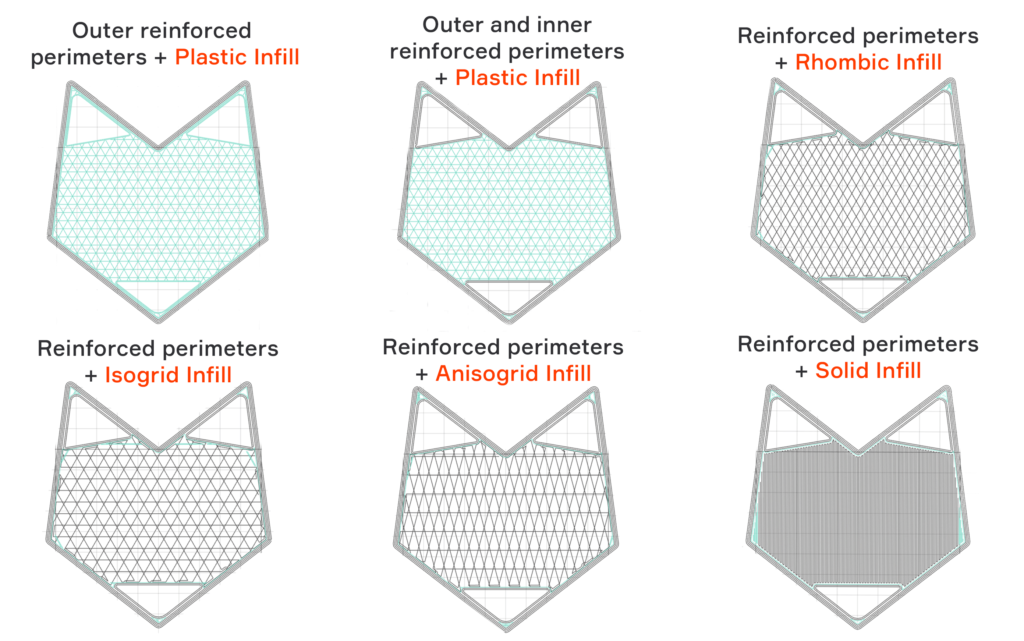

To help you with reinforcement of a part we developed slicer Aura. Aura algorithms are based on our intuitive vision of how composites should work. You can reinforce external and internal boundaries of each layer of the part with one or several fiber perimeters, so called outer and inner perimeters. You can also reinforce inner space of the part with solid (conventional laminate) or lattice patterns. Such reinforcement is called reinforced infill. Different layers or groups of layers can have different reinforcement.

Loaded Elements Suitable for Manufacturing on Composer

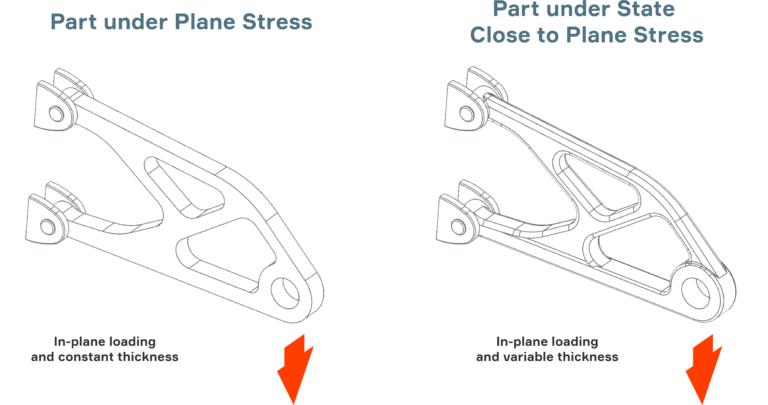

Elements under plane stress means rather thin parts that are subjected to in-plate loads and loads do not change through the part thickness. When out-of-plane loads for real thin parts are small and neglectable these parts can be considered as under plane stress. Manufacturing of such parts is the best way for application of CFC printing.

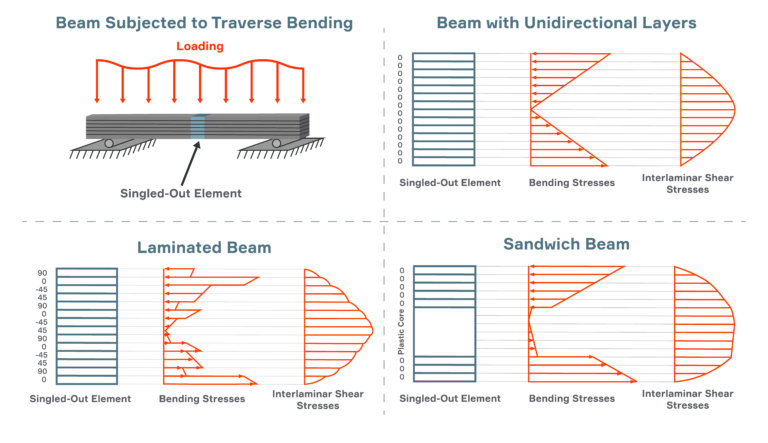

Elements under bending are also mostly subjected to in-plane loading. So, in contrast to plane stress state, acting stresses vary through the element thickness. The greatest stresses are close to the external surfaces of the part. In addition to in-plane stresses, interlaminar shear stresses accompany the bending in most of cases. Maximum interlaminar shear stress is close to central layers. As a rule, the interlaminar shear stress is much less than in-plane stresses and the smaller thickness-to-length ratio for the part the less interlaminar shear stress in comparison to in-plane stress.

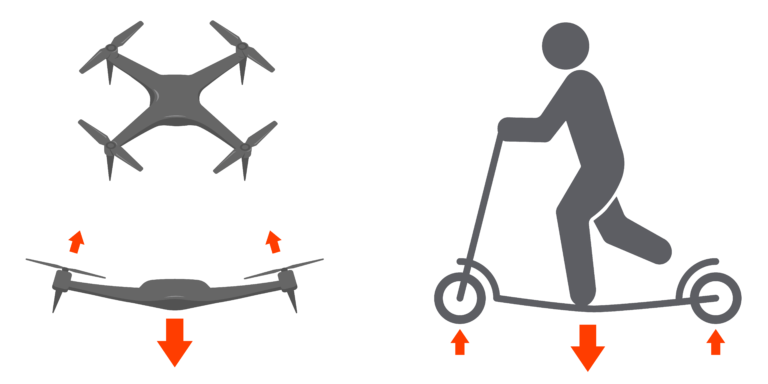

Examples of structural elements under the bending

If a loaded structure is complicated and it does not directly comply with description above sometimes an engineer can split such structure on simple structural elements subjected to in-plane loading and the final structure will become an assembly.

General Structure of CFC Printed Composites

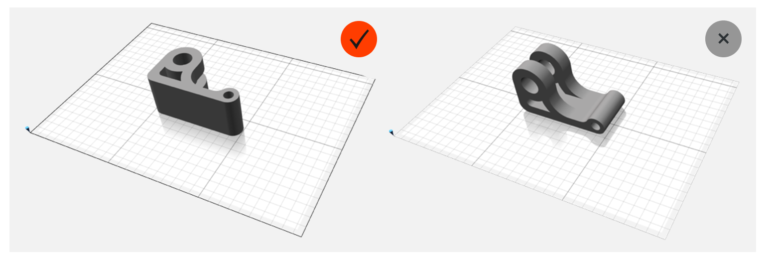

As in Fused Filament Fabrication (FFF), parts made by Composite Filament Co-extrusion (CFC) process are layered structures. Parts printed by Composer consist of flat reinforced layers.

This means that the CFC printed parts can effectively carry loads acting in planes parallel to buildplate surface. Thus, you need to design the part in such a way that all reinforced layers become parallel to the loading plane. At the same time, the loading plane should be parallel to the buildplate surface when you print the part.

We do not recommend to manufacture very high parts by CFC printing. The high parts do not possess high strength in Z direction and can be broken under interlaminar loads. Recommended height of CFC printed part should not exceed the minimum overall dimension of the part in XY plane. If you plan to print part with big height, do it just by FFF printing.

Understanding Composites

Anisoprint technology is intended to produce lightweight, stiff and strong composite parts. Understanding composites is crucially important to extract maximal profit from the technology. Therefore, we wrote this guide to share our vision of composites and to assist you in understanding of these awesome materials.

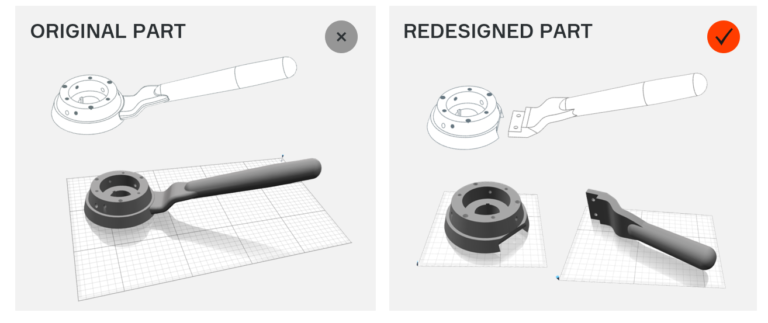

Stop Metal Thinking

In conclusion of this guide, we would like to make a very important point. Composites are completely different from conventional materials (metals, plastics etc.). They are significantly anisotropic and inhomogeneous. This means that a metal (plastic) part and a composite part having the same purpose have to possess completely different designs! If you want to substitute a metal part with a composite part you should redesign one.

Note

Never adopt a metal driven design for composite parts!

Stop metal thinking – start Anisoprinting 😉

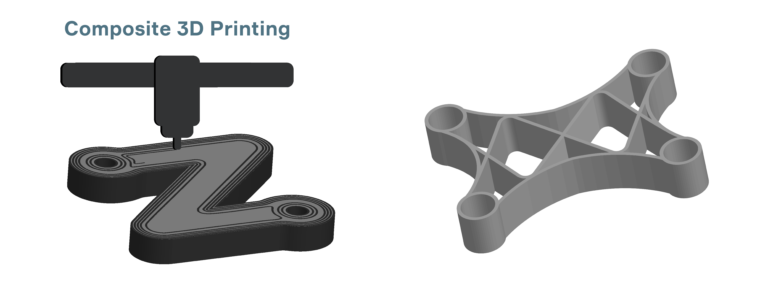

3D Printing of Composites

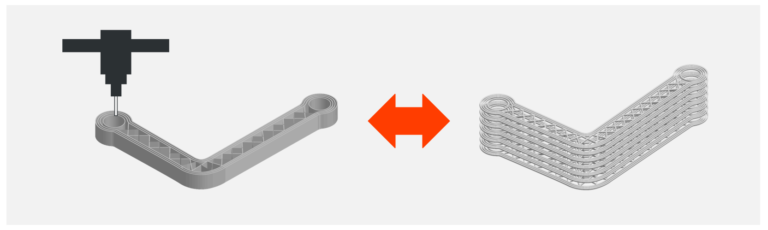

Currently, only 3D printing allows to obtain composite parts with complex shape and high flexible fiber reinforcing paths. With 3D printing you can control anisotropy and utilize potential of fiber reinforcement with maximum efficiency. By the way, that’s why we are called Anisoprint (anisotropic printing or printing with control of anisotropy). You do not need to cut fibers. You can manufacture any hole in composite part without drilling and with reinforcement. Moreover, Anisoprint technology (Composite Fiber Coextrusion) uses thermoplastic matrix that increases impact resistance of a part in contrast to conventional thermosetting composites.

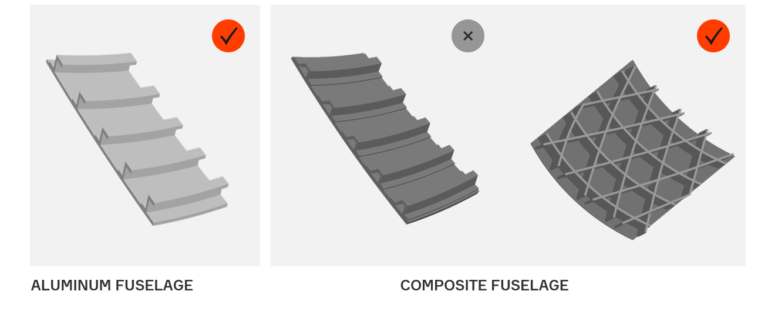

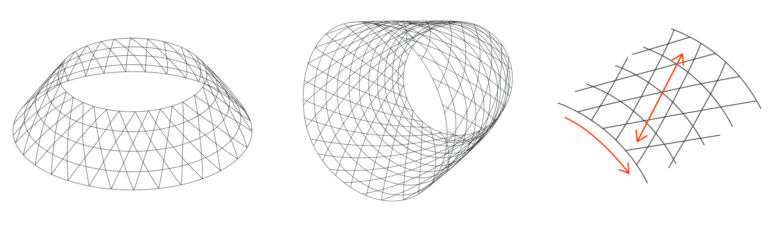

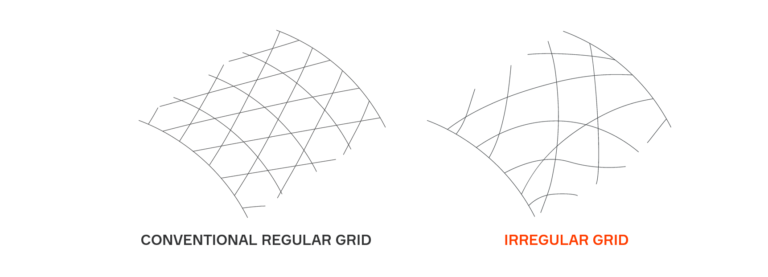

Lattice Structures. Advantages and Restrictions

The most effective way to utilize potential of fiber reinforcement is lattice anisogrid structures. The peculiarity of the structures provides an effective distribution of loads along the fibers because the major acting loads run along the grid ribs i.e. in fiber direction. Thus, lattice anisogrid structures possess high weight efficiency in contrast to laminates.

The lattice structures are not afraid of cutouts and do not need drilling and milling. For these structures you can use special inserts.

Conventional composite technologies (winding, fiber placement) can produce parts only with geodesic and quasi-geodesic reinforcement paths, and regular grids. Structures with irregular grid density and non-geodesic reinforcement could provide more efficient distribution of acting loads and, as a result, weight reduction. However, such structures cannot be obtained by the conventional technologies.

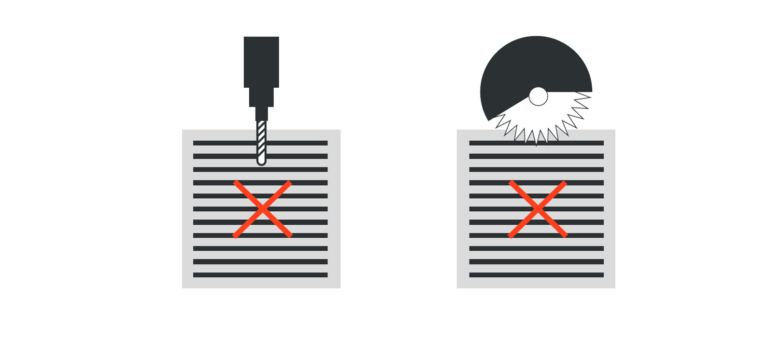

Machining of Composites

If you need to joint composites or make some kind of hatch in a composite structural element, you will encounter the fact that you need to drill, mill or cut the composite material. Drilling, milling and cutting significantly reduce strength of reinforced composite in vicinity of the machined edge. The strength can drop down several times! So, the machining is actually killing the idea of reinforced composites application.

Note

Avoid drilling, milling and cutting reinforced composites! They do not like it!