Your Composer had already been pre-calibrated before shipping, but due to transport vibrations, it could be uncalibrated. Thus, you may need to go through the entire calibration procedure after the printer installation.

NOTICE: Clean and preheat the nozzles and the buildplate to its printing temperatures before all the calibration procedures (buildplate, Z axis, Z-offset) to prevent incorrect calibration.

NOTICE: Clean and preheat the nozzles and the buildplate to its printing temperatures before all the calibration procedures (buildplate, Z axis, Z-offset) to prevent incorrect calibration.

You need to go through the buildplate calibration procedure after any changes affecting the positioning of the buildplate, e.g. shaking or moving the printer. While printing a large part occupying the whole buildplate area, you can notice layer thickness varies from one end of the part to another, which as well means the buildplate requires recalibration.

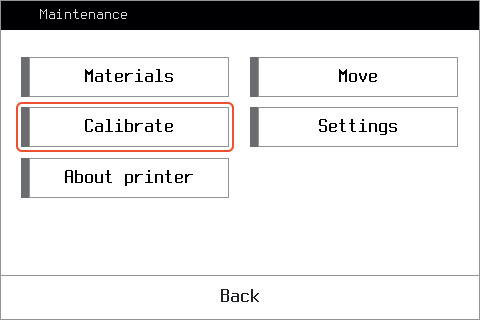

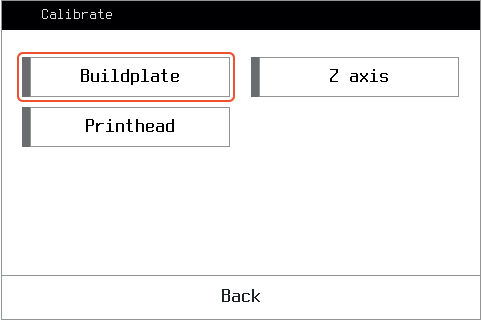

To start the calibration, go to the main screen, press Maintenance >Calibrate > Buildplate. Follow the instructions. First, you will be asked to set the plastic nozzle in approximately 1 mm from the buildplate. The first of 3 points is to be set through the calibration menu,

the left and right corners are tuned manually by adjusting the regulation screws. Second, the procedure is to be repeated for fine-tuning, this time using a sheet of 80gsm paper to set the lowest possible gap between the nozzle and the buildplate. The paper must be sliding in the gap with slight friction.

It is recommended to calibrate the Z-axis right after the buildplate calibration.